Centrifugal pumps are used in various industries due to their simplicity and the availability of spare parts. They are simple to install, maintain, and use in clean-in-place (CIP) systems. These pumps can effectively transfer liquids of varying viscosities and are available with multiple seal options.

When working with these pumps, there are a few key parameters to keep in mind. Firstly, centrifugal pumps are not self-priming, which implies that they cannot pump air, so the pump must be primed, or filled with liquid, before it can begin pumping. Additionally, centrifugal pumps are not reversible, meaning that they cannot change the direction of the flow once it has been established. This indicates that the pump must be properly installed and configured in order to pump in the proper direction. These limitations should be considered when selecting a centrifugal pump.

Centrifugal pumps are reliable and inexpensive pumps that are used in a variety of industries, but like any piece of machinery, they do require regular maintenance to ensure they continue to operate effectively. Annual seal replacement is one of the most important maintenance tasks for centrifugal pumps. This is because seals can wear out over time, leading to leaks and other problems. In addition to annual seal changes, daily clean-in-place (CIP) procedures are required to keep the pump and its components free of debris and other contaminants. This will help to extend the life of the pump and avoid expensive repairs or replacements. Overall, regular maintenance is crucial for keeping centrifugal pumps working effectively.

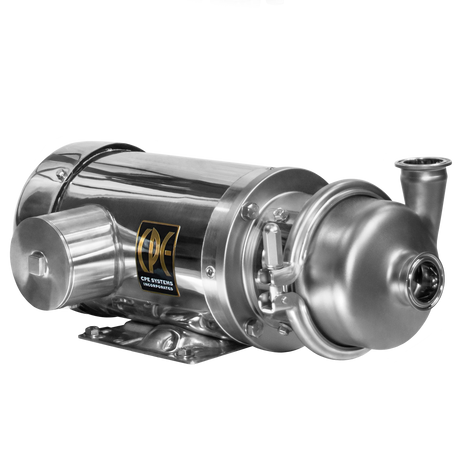

C-Series Centrifugal Pumps

Our most popular centrifugal pump is the C-Series. This series is designed to handle liquids containing semi-solids and low to medium viscosity products at a high GPM and pressures up to 60 PSI. With a wide range of seal options to choose from, the seal is designed to last longer thanks to our unique wave spring, which ensures even pressure on the seal, reducing wear.

Another significant advantage of this pump is the upgraded shaft and collar design on our C-Series and C+Series pumps. They feature a collar that clamps down on the drive shaft over the full 360 degrees, removing the minor wobble that can occur from set screwed shafts. This ensures better shaft centricity, resulting in a pump that is quieter and lasts longer. The C-Series pumps come in a full range of sizes, with connection sizes ranging from 1" to 6" in diameter.

Not sold yet? Our C-Series has the ability to be equipped with an explosion-proof motor, making it suitable for use in volatile environments.

| Impeller Types | Motor Types | Seal Types | Industries | Operation Capacity | Price |

|---|---|---|---|---|---|

| Open | SS AC Induction | External Balanced "D" | Food | Nano - Large | $$$$ |

| TEFC | Water Cascade "F" | Beverage | |||

| Explosion Proof | External Balanced "DG" with clamped-in seat | Pharmaceutical | |||

| Water Cooled Double Balanced "E" | Sanitary Processing |

SIDE NOTE:

The C100, C+100, and MB 100 are all sanitary centrifugal pumps with an external mechanical seal. The C100 is the base model, the C+100 is an upgraded version with improved shaft design and better shaft centricity. To ensure maximum efficiency, we have included a high-pressure backup ring that holds the o-ring in place within the seal. This reduces the possibility of the o-ring slipping out of place under pressure and causing leakage. The MB 100 is a re-engineered version designed with a silicon carbide stationary seal-face with a carbon rotary seal (aka DG seal) for improved reliability, dependability, and performance.

The C100 can be upgraded to the C+100 for no extra cost.

C+Series Pumps

The C+100 series pump is the original C-series pump reimagined. It has all the features of the original C-Series pumps, including the casing design and popular external mechanical seal options, as well as the improved drive shaft design mentioned above. Another key improvement in the C+ Series is the replacement of the impeller pin with a threaded impeller nut. This fully secures the impeller in place, providing added stability and reducing the likelihood of impeller movement or rattling sounds at lower speeds. To further enhance this stability, the C+ Series also includes two specialized gaskets to seal the shaft and impeller, and to still allow the CIP procedure to fully clean the interior of the pump.

| Impeller Types | Motor Types | Seal Types | Industries | Operation Capacity | Price |

|---|---|---|---|---|---|

| Open | SS AC Induction | External Balanced "D" | Food | Nano - Large | $$$$ |

| TEFC | Water Cascade "F" | Beverage | |||

| Explosion Proof | External Balanced "DG" with clamped-in seat | Pharmaceutical | |||

| Water Cooled Double Balanced "E" | Sanitary Processing |

CB+ Series Pumps

Our CB+ series pump is distinguished by an internal mechanical seal that facilitates cleaning, prevents pooling, and allows for higher seal pressure with less leakage.

When working with sugary substances like wort, internal seals are the preferred method. With an internal seal, the seal is constantly awash with the fluids in the pump head and is completely rinsed during CIP procedures, reducing the buildup of sugar crystals and extending seal life. This makes it an ideal pump for use in breweries, where sugary substances are regularly pumped. The issue with external seals working with sugary substances is that sugar crystallization can easily occur. This happens due to the seal using small amounts of the pumped fluids to lubricate the surfaces between the seal. Once the sugar crystallizes, it can rub against the seal, wearing it down over time.

The CB+ pump is built with the same shaft collar and threaded impeller nut as the C+ pumps. Together, the collar and bolted impeller design minimize rattling at lower speeds, making it more reliable in operation. This is especially useful for craft brewing and distilling, where low-speed operation is required for precise control over the process.

Additionally, the pump uses specialized gaskets to seal the impeller to the shaft and enable CIP cleaning behind the impeller.

| Impeller Types | Motor Types | Seal Types | Industries | Operation Capacity | Price |

|---|---|---|---|---|---|

| Open | SS AC Induction | External Balanced "D" | Food | Nano - Large | $$$$ |

| TEFC | Water Cascade "F" | Beverage | |||

| Explosion Proof | External Balanced "DG" with clamped-in seat | Pharmaceutical | |||

| Water Cooled Double Balanced "E" | Sanitary Processing |

SEN Series Pumps

The Hyginox SEN series is a sanitary centrifugal pump specifically designed for the dairy, beverage, and food-processing industries. Its internal mechanical seal helps prevent product build-up, reduces leakage, and is capable of self-cleaning during CIP processes.

The Hyginox's high efficiency makes it ideal for handling delicate liquids and hot water transfers. It's a pump that just keeps going, which is exactly what you need when brewing a variety of styles.

In addition, the Hyginox can be fitted with an explosion-proof motor, making it suitable for dealing with high-proof alcohol and volatile environments.

| Impeller Types | Motor Types | Seal Types | Industries | Operation Capacity | Price |

|---|---|---|---|---|---|

| Open | SS AC Induction | Internal Mechanical | Food | Nano - Large | $$$$ |

| Explosion Proof | Beverage | ||||

| Pharmaceutical | |||||

| Sanitary Processing |

RVN Series Pumps

The RVN series pump is ideal for handling semi-solid liquids like mash and must in winery applications. Its large helicoidal impeller and inlets enable it to handle larger solids like whole grapes with low shear. This feature is especially useful in winery applications, where the pump must handle a wide range of semi-solid materials without causing damage to the product.

The RVN pump has an internal mechanical seal made partly of silicon carbide. This material is well-known for its durability and ability to withstand the high temperatures and pressures encountered in winery applications.

Additionally, the pump casing also features a drain port, which allows for easy cleaning and maintenance of the pump.

| Impeller Types | Motor Types | Seal Types | Industries | Operation Capacity | Price |

|---|---|---|---|---|---|

| Helicoidal | SS Washdown | Internal Seal | Food | Small - Large | $$$$ |

| Explosion Proof | Beverage |

QIM Series Pumps

The QIM Shear pump is ideal for pumping applications that require homogenization or disintegration. Its unique inline mixing capability is what defines the QIM series from the rest of the centrifugal pump family. It features a stator with several options for radial openings to choose from! The QIM series impeller pushes the fluid through the stators, effectively breaking up any solids in the fluid. This process results in a homogenized mixture.

The stators are interchangeable and can be swapped if the pump is being used for multiple applications. Choosing the right stator will depend on the specific application and the type of product being pumped:

-

The large radial bores are designed to cut up soft solids into smaller particles.

-

The small radial bores are ideal for the emulsification of different liquids.

-

The Straight Radial Slots are designed to disintegrate lumps and for powder induction.

The QIM pump's semi-open impeller aids in keeping the mechanical seal lubricated and pressurized, ensuring smooth and efficient operation. While the casing's o-ring ensures maximum dependability without the possibility of leakage.

To simplify, the QIM Shear pump is a versatile and cost-effective solution for industries requiring homogenization or decomposition during pumping. Due to its ability to easily swap the stators, it can be used for a variety of industries and products.

| Impeller Types | Motor Types | Seal Types | Industries | Operation Capacity | Price |

|---|---|---|---|---|---|

| Open | SS Washdown | Single Mechanical Internal Seal | Food | Small - Large | $$$$ |

| Beverage | |||||

| Pharmaceutical | |||||

| Sanitary Processing |

Centrifugal Pumps Conclusion

Centrifugal pumps are a popular choice for their ease of use, reliability, and cost-effective parts. Before purchasing a centrifugal pump, keep in mind that it must be primed before you can begin pumping your product. If you require a self-priming pump, we have multiple other options available for you. That being said, they are a long-lasting pump that can handle a wide range of viscosities, alcohol levels, and solids, and provide homogenization when required.